Mining

Notebook

Hand

Sluicing for Gold

Equipment needed:

Portable sluice box, sieve, suitable shovel, 5 gallon plastic pails, 2 gold pans, pry bar, crevice tool and a pick.

Among

the more popular sluice boxes in use today are two lightweight aluminum

models from Keene Engineering. The A51 Mini Sluice weighs in at seven

pounds, while the larger A52 Hand Sluice tips the scales at eleven pounds.

One of the most practical methods of gold prospecting and recovery involves

the use of a piece of equipment that has been in use for over a hundred

years. One of the very best gold gathering devices on the market today

is still the Hand Sluice.

Among

the more popular sluice boxes in use today are two lightweight aluminum

models from Keene Engineering. The A51 Mini Sluice weighs in at seven

pounds, while the larger A52 Hand Sluice tips the scales at eleven pounds.

One of the most practical methods of gold prospecting and recovery involves

the use of a piece of equipment that has been in use for over a hundred

years. One of the very best gold gathering devices on the market today

is still the Hand Sluice.

Sluice

boxes were once built at the location of the mining site from the material

that were on hand such as heavy wood planks and logs. Often the river

current was diverted through the sluices so that gold-bearing gravels

could be processed far quicker than using the laborious "hand panning"

method. The old sluice boxes were lined with raised obstructions that

were placed in a vertical position to the flow of the current. (These

obstructions were later referred to as riffles)

Sluice

boxes were once built at the location of the mining site from the material

that were on hand such as heavy wood planks and logs. Often the river

current was diverted through the sluices so that gold-bearing gravels

could be processed far quicker than using the laborious "hand panning"

method. The old sluice boxes were lined with raised obstructions that

were placed in a vertical position to the flow of the current. (These

obstructions were later referred to as riffles)

When

the gold-laden gavels were dumped into the upper end of the sluice, the

flow of water carried the material down the length of the box. The lighter

gavels (tailings) would be carried in suspension down the entire length

of the sluice and then discharged. The heavier material (such as gold,

platinum metals and black sands), would quickly drop to the bottom of

the box, where they became entrapped by the riffles. Once the riffles

collected a large quantity of concentrated black sand, a "cleanup"

was implemented. The flow of water through the sluice would be diminished

by a type of water gate. Then the riffles would be removed, allowing access

to the heavier materials, which had collected during the "run."

This remaining material or concentrate often contained all the values

amounting to many tons of gravel which had to be tediously panned.

When

the gold-laden gavels were dumped into the upper end of the sluice, the

flow of water carried the material down the length of the box. The lighter

gavels (tailings) would be carried in suspension down the entire length

of the sluice and then discharged. The heavier material (such as gold,

platinum metals and black sands), would quickly drop to the bottom of

the box, where they became entrapped by the riffles. Once the riffles

collected a large quantity of concentrated black sand, a "cleanup"

was implemented. The flow of water through the sluice would be diminished

by a type of water gate. Then the riffles would be removed, allowing access

to the heavier materials, which had collected during the "run."

This remaining material or concentrate often contained all the values

amounting to many tons of gravel which had to be tediously panned.

Any

miner or prospector will tell you that portability is the key to success.

Most of the gold deposits that easily accessible have long since been

depleted of their gold. Today you will have to "get off the beaten

path" to find any virgin areas. During the Gold Rush sluices were

first used to work the extremely rich bench deposits "terrace"

gavels" which lined the banks of many Mother Lode Rivers. As time

passed it became clear that sluice boxes could be used for working other

types of gold-bearing material, to include ancient river channel deposits

located hundreds of feet above the existing stream beds.

Any

miner or prospector will tell you that portability is the key to success.

Most of the gold deposits that easily accessible have long since been

depleted of their gold. Today you will have to "get off the beaten

path" to find any virgin areas. During the Gold Rush sluices were

first used to work the extremely rich bench deposits "terrace"

gavels" which lined the banks of many Mother Lode Rivers. As time

passed it became clear that sluice boxes could be used for working other

types of gold-bearing material, to include ancient river channel deposits

located hundreds of feet above the existing stream beds.

Modern prospectors use sluice boxes to work literally any type of gold-bearing

gravel which can not be worked with a suction dredge. Sluice box's have

been successfully used to process gold bearing gavels located in dry desert

areas, by utilizing transported in water and recirculation systems.

In

many cases today's prospectors use their sluice boxes to work areas located

adjacent to flowing streams. Frequently, people who own suction dredges

will carry in a lightweight sluice box to sample gravel bars they may

wish to dredge at later date. If it turns out a gravel bar is not as rich

as originally believed, all the labor of carrying in a large equipment

may be avoided. For the benefit of those who are not familiar with the

proper use of a sluice box, I will explain the basic principles involved.

As you will learn shortly, they are not the least bit complicated. Anyone

can be come a qualified "sluice operator" after just a few hours

time spent in the field! The sluice boxes in the days of the 49'ers were

very similar to the ones of today. The primary difference is the construction

and materials. Sluice boxes were built of heavy wood planks, because lumber

was cheap and easily obtainable. Today's sluice boxes are constructed

of light weight aluminum and steel.

In

many cases today's prospectors use their sluice boxes to work areas located

adjacent to flowing streams. Frequently, people who own suction dredges

will carry in a lightweight sluice box to sample gravel bars they may

wish to dredge at later date. If it turns out a gravel bar is not as rich

as originally believed, all the labor of carrying in a large equipment

may be avoided. For the benefit of those who are not familiar with the

proper use of a sluice box, I will explain the basic principles involved.

As you will learn shortly, they are not the least bit complicated. Anyone

can be come a qualified "sluice operator" after just a few hours

time spent in the field! The sluice boxes in the days of the 49'ers were

very similar to the ones of today. The primary difference is the construction

and materials. Sluice boxes were built of heavy wood planks, because lumber

was cheap and easily obtainable. Today's sluice boxes are constructed

of light weight aluminum and steel.

SLUICING

INSTRUCTIONS

GETTING

SET UP

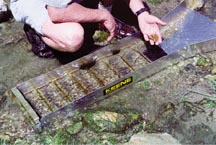

After you have located a promising deposit of gold-bearing gravel, walk

along the stream bank and look for a place where you can set up your sluice

box. You should search for a spot where the current is moving quite swiftly.

Once you find such a place, set your sluice box directly in the current

so that the box is filled with water almost to the top. You can often

compensate by placing the sluice box so that the upper "input"

end is slightly higher than the lower "discharge" end. If the

sluice box is somewhat unstable in the current, position a few rocks around

the outside of the trough to brace it. Sometimes you will not even need

the "rock brace," as the first few buckets of gravel placed

into the sluice box will provide just enough stability to weigh it down.

Once

you have located a good deposit of gold-bearing gravel set up your sluice

box at any nearby place where the stream current Is flowing quite swiftly.

The water depth should be nearly to the top of the sluice trough. Feed

the gold-bearing gravel Into the upper end of the sluice box in carefully

regulated amounts. Do not dump the entire bucket into the sluice box all

at once. The proper Introduction of gravel will ensure maximum riffle

efficiency and optimal fine gold recovery.

FEEDING

THE SLUICE

Feed your gold-bearing gravel into the upper portion of the sluice box

in carefully regulated amounts. Do not, under any circumstances, dump

a large amount of gravel into the sluice box all at once! The gravel must

be fed at a pace that will not overload the riffles. How can you tell

when the riffles are overloading? It is simple. If you cannot see the

uppermost "crest" of each riffle bar at all times, you are feeding

the gravel too fast. Back off a bit. The use of a 1/4 inch classifier

screen to pre-screen material before dumping into the sluice box can save

much time and effort. The penalty for overloading your riffles often results

in lost gold! Each time a new load of gravel is dumped into a sluice box

with overloaded riffles, any gold in that gravel will wash right over

the material that is clogging your riffles and out the discharge end of

the box.

Classifier

screens are available in many sizes to fit both gold pans and various

size buckets. SIEVE PIC

CHECK

THE SLUICE FOR VALUES

It is a good idea to periodically check the sluice box for values that

may have been recovered. The black rubber matting is designed to make

a quick inspection during the sluice operation. Gold can be spotted instantly

on the black matting while the sluice is being fed. This helps to determine

where the gold values may be the most plentiful. Remember, don't overload

your riffles!

TENDING

THE SLUICE

After dumping each load of gravel into the sluice box, check the riffle

section for large waste rocks that may be lodged in the sluice. Flick

these rocks out of the riffles with your fingers. When large rocks are

allowed to rest in the riffle section they will cause the current to wash

out all the concentrates from the immediate area of the rock. If a rock

is lodged in the uppermost portion of the trough, the washed out concentrates

will merely settle in the next few riffles down. But if the wash-out occurs

at the lower end of the trough, the concentrate may flow out of the sluice

box altogether. As one can see, it pays to keep an eye on those waste

rocks! And one more thing, don't forget to shovel away the tailings which

will periodically build up at the discharge end of the sluice box. If

you don't the tailings will back up into the lower end of the sluice trough,

burying some of your riffles. Remove large rocks that may cause values

to wash away. Shovel the material that has built up at the end of the

sluice to prevent any obstruction that may prevent the flow of material.

Remove the sluice's riffle section, screen, carpet and wash into a pan

or bucket carefully.

After dumping each load of gravel into the sluice box, check the riffle

section for large waste rocks that may be lodged in the sluice. Flick

these rocks out of the riffles with your fingers. When large rocks are

allowed to rest in the riffle section they will cause the current to wash

out all the concentrates from the immediate area of the rock. If a rock

is lodged in the uppermost portion of the trough, the washed out concentrates

will merely settle in the next few riffles down. But if the wash-out occurs

at the lower end of the trough, the concentrate may flow out of the sluice

box altogether. As one can see, it pays to keep an eye on those waste

rocks! And one more thing, don't forget to shovel away the tailings which

will periodically build up at the discharge end of the sluice box. If

you don't the tailings will back up into the lower end of the sluice trough,

burying some of your riffles. Remove large rocks that may cause values

to wash away. Shovel the material that has built up at the end of the

sluice to prevent any obstruction that may prevent the flow of material.

Remove the sluice's riffle section, screen, carpet and wash into a pan

or bucket carefully.

PERFORMING

THE CLEANUP

When your riffles have accumulated black iron sand in amounts extending

more than halfway downward to the next lower riffle, it is time to perform

a cleanup. Carefully lift the sluice box from the current keeping it as

level as possible. Now carry it over to the stream bank (watch your footing

on those slippery rocks!) and set it down. Remove the sluice's riffle

section and screen and set it aside, exercising care not to shake off

any gravel adhering to it. Roll up the matting which lines the bottom

of the sluice box trough and thoroughly rinse off all the concentrate.

This should be done with the matting safely contained in a gold pan or

deep bucket if possible. The use of a bucket may prevent any loss of all

gold that could occur when attempting to rinse out the matting in a gold

pan! Next, examine the empty sluice box trough.

Gold

has a tendency to work its way beneath the matting which often lies at

the bottom of the trough. You may be surprised at the amount of "color"

that can accumulate there. Check to see if there is any fine silt clinging

to the bottom, rinse all of it into your concentrate bucket. Finally,

pick up the riffle section itself and rinse any adhering gravel into the

concentrate bucket. The sluice box cannot be considered "cleaned"

until each and every part has been thoroughly rinsed.

After

the riffle section has been removed, roll up the matting which lines the

bottom of the sluice box trough and thoroughly rinse it off in a pan or

bucket. The concentrate rinsed from the matting will contain most of the

gold accumulated during the "run. Once the sluice's bottom matting

has been rinsed, check the empty trough for fine silt which may have worked

its way beneath the matting. If silt is present, rinse all of it into

the concentrate bucket. Also rinse off the riffle section and screen and

black matting. You may be surprised at the amount of color that can accumulate!

The final step of the sluicing is the panning of the concentrates, to

get the gold out. Do this very carefully, since the material in your pan

contains all the gold once spread throughout the many hundreds of pounds

of gravel you have processed through your sluice.

GETTING

THE GOLD OUT

And now for the final step. This is the one you will certainly enjoy the

most. The act of panning out your concentrates to get the gold. I hope

your run was a profitable one!

SUMMATION

By the time you get to the last step, you will have processed several

hundred pounds of gravel, far more than the average person could ever

hope to hand-pan during a daily outing. Using a sluice box of the type

shown, you can also work this much gravel. All you need is a sturdy shovel,

a couple of good buckets to carry gravel to the creek, and if your fortunate,

a mining partner to feed the sluice box while you dig gravel, and a solid

desire to get that gold.

The

Blue Bowl concentrator can recover Gold as fine as talcum powder when set

up and used properly, eliminating hours of tedious finish panning. Click

the Blue Bowl image to learn more about it, and micro Gold recovery techniques.

The

Blue Bowl concentrator can recover Gold as fine as talcum powder when set

up and used properly, eliminating hours of tedious finish panning. Click

the Blue Bowl image to learn more about it, and micro Gold recovery techniques.